Workshop story — craft, precision and collaborative design

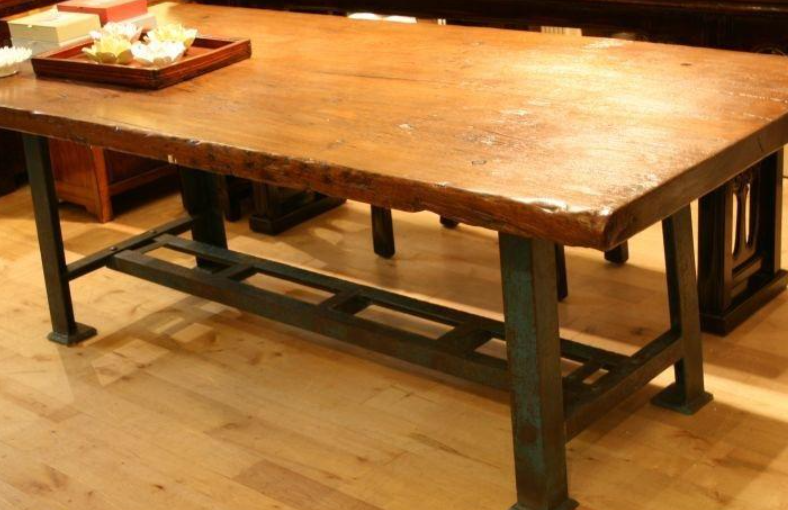

Our workshop unites traditional joinery skills with modern manufacturing controls to produce custom furniture tailored to the way people live and use spaces. From the first consultation, we map out practical programmatic needs—storage, ergonomic clearances, user flows—and translate those into design solutions that balance function and aesthetics. We rely on timber species chosen for structural performance and visual warmth; each board is inspected, acclimatised and prepared with milling and moisture control to avoid future movement. CAD-driven nesting reduces waste in cutting, CNC routing handles complex joinery accurately, and hand-finishing restores human touch to edges, dovetails and exposed surfaces. On-site installation includes careful leveling, anchoring and final finish touch-ups that make the piece feel integrated rather than merely placed.

Quality assurance is carried out at multiple checkpoints: material incoming inspection, mid-process fit trials, surface sanding and finish adhesion tests, and a final sign-off with the client. We document dimensions and shop settings for future reference, enabling repair, expansion or matched additions years later. Our team includes designers, experienced cabinetmakers, finishers and installation specialists who coordinate with architects or interior designers to ensure timing and access match project schedules. Sustainability is an operational value: we source local timbers where possible, use low-VOC finishes, and reclaim surplus boards into secondary products or client-supplied pieces to minimize waste.